NOIL®

Oil-Free Hydraulic Fluid

When you can’t afford to foul up.

Solve all the profit-draining problems of hydraulic oil leaks with Kaady’s revolutionary, water-based synthetic lubricant. Formulated to perform exactly like hydraulic oil, NØIL has none of its typical problems: No oil in your reclaim, no oil on your customers vehicles, no oil on your cloth or other cleaning media, no petroleum in your sanitary sewer system. (NØIL also solves the problem of oil in your closed-loop system.) And, when it comes to corrosion protection, NØIL has lubricating properties that are actually superior to oil. What’s more, the bright orange color affords quick detection of leaks. (NØIL is compatible with all other water based synthetic lubricants sold to the car wash market. Lab report available on request)

Solves the problem of overheated hydraulic fluid.

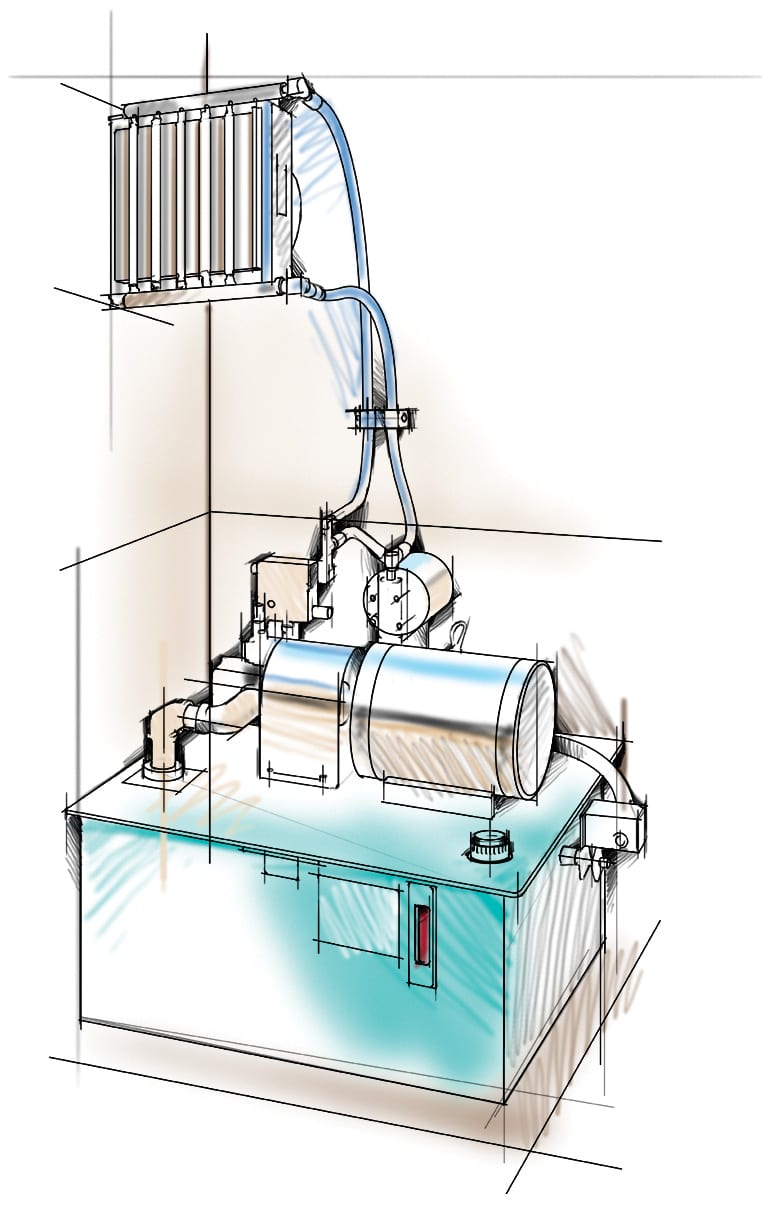

The NØIL® In-Line Cooling System is designed to lower the operating temperature of NØIL Oil-Free Hydraulic Fluid. Higher than normal operating temperatures can be experienced by older type hydraulic units, or locations where equipment room temperatures are extreme. Higher operating temperatures (120° – 150°) can cause some fluid evaporation. The cooling system will reduce operating temperatures up to 50°, thus saving product. The NØIL In-Line Cooling System will reduce your overall hydraulic system operating cost.

System Specifications

- Single-phase, 120 volts, 15 amps

- Plumbing required from hydraulic return line to tank

- S.O. cord or conduit per code required

- Max temperature 350°

- Will remove 30° of input H.P., up to a 50° temperature reduction

- Pressure drop is less than 25 psi at full flow

- Rated for hydraulic units up to 24GPM

Converting From Hydraulic Oil to NØIL®

Recommended Supplies:

- Rags or paper towels

- Small pump

- 55 gallon drum

- 6 gallon pails

- Wet/dry vacuum

- 60 mesh inlet strainer

- 10 micron filter element

Procedure:

- Drain or pump out of fill hole as low as possible into 55 gallon drum, or lift cover plate.

- Finish draining through clean-out plug.

- Install 60 mesh strainer.

- Change out return filter with 10 micron filter element.

- Disconnect return line and drain into 55 gallon drum.

- Fill tank with NØIL to top of sight gauge.

- Start system and watch return line until all hydraulic oil is purged from system.

- Shut down system and reconnect return line.

- Refill tank to top of sight gauge.

- Start system and check all motors, pumps and fittings for leaks.

- Keep an eye on fluid and skim off any hydraulic oil that rises to the top of NØIL in tank.

Maintenance Tips:

- Maintain NØIL to top of sight gauge.

- Regularly check PH of NØIL; maintain between 8 and 10.

- If NØIL PH gets below 8 or greater than 10, replace NØIL in system and tank.

- Recommended operating temperature not to exceed 120°. Keeping your tank full or a larger tank will help maintain proper temperature.

NØIL® Operating Guidelines and Hydraulic System Tips

- Refer to the NØIL sell sheet for operating specifications. NØIL is designed for hydraulic units rated up to 2000 PSI pressure. Refer to the “Compatibility” information on the NØIL brochure for hydraulic components compatible with the NØIL fluid.

- Maintain NØIL fluid level within hydraulic tank just below the top of the sight gauge; keep the tank full to minimize heat within the system. A larger hydraulic tank reservoir will also assist in maintaining proper operating temperature.

- Recommended operating temperature not to exceed 120°. For higher operating temperatures, the “NØIL In-line Cooling System” is recommended. For extreme temperature situations a larger cooling system may be required. The NØIL In-line Cooling System is rated for hydraulic units up to a 24 GPM capacity.

- Regularly check the PH of NØIL. Maintain between 8 or 10. If the PH is lower than 8 or above 10, replace the NØIL within the system and hydraulic tank. Contamination within the hydraulic system will cause the NØIL PH levels to get out of balance.

- Check the hydraulic tank float switch for proper adjustments. Set the float switch so when the unit is in operation, the system will loose only 1 to 2 gallons of fluid before the switch will activate.

- Replace the 10-micron filter every 8 to 10 months. A pressure gauge prior to the return filter will assist you in determining when the filter begins to experience an increase in pressure due to particulate build-up. The backpressure should not exceed 15 to 25 PSI.

- Check the hydraulic pump monthly for excessive vibration. Insure that the internal intake pipe and the return line orifice are fully submerged. Check the motor coupling for smooth movement.

- Check hydraulic lines and hoses. Ensure that the fluid flow is smooth and not erratic. Check the hydraulic system return line, replace if it appears worn or soft. We recommend using the following products for hose & seals compatibility; Buna-N, Viton or EPR Viton is preferred, Polyurethane seals should be avoided.

- Kaady Chemical recommends that you replace the NØIL product within the hydraulic system every 1 to 2 years dependant on the wash volume and/or the age of your hydraulic system and plumbing.